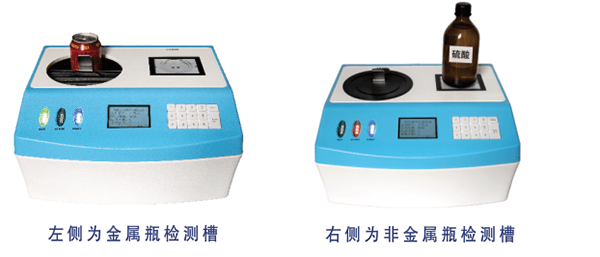

1. Product introduction:

ZJSC-680 desktop dangerous liquid detector of the new generation of liquid detection equipment. Using ultra-wideband pulse microwave reflection method and thermal conductivity method, suitable for inspection of various common packaging liquids such as glass, plastic, metal, ceramics, etc., and can automatically detect flammable, explosive, and corrosive without opening the liquid packaging Sexually dangerous liquid, and the recognition rate is accurate and efficient. Its purpose is to prevent dangerous liquids (which can cause burning or explosive liquids) from entering safe areas, and can be widely used in stations, subways, government agencies, sports venues and other crowded and important event venues necessary for safety inspection.

2. Leading advantage

Quick analysis: the detection time of non-metallic bottle liquid is less than 1 second, and the detection time of metal bottle liquid is less than 3 seconds. At present, the fastest liquid detector in the industry is fully adapted to the rapid safety inspection during the peak flow of people.

Bottle bottom detection: The world‘s original bottle bottom detection technology, the only instrument that passes the bottom detection of the container, without having to leave a lot of liquid in the container to be tested.

Sulfuric acid alarm: the only sulfuric acid detection in the world, the only liquid detector in the industry that can detect sulfuric acid, even dilute sulfuric acid can be tested 100% accurately.

Environmental protection design: Adopt green environmental protection design, adopt ultra-wideband pulse microwave reflection method and thermal conductivity method, do not contain radiation, harmless to human body and tested items, and the detection method is environmentally friendly and safe.

Alarm mode: the detection result is through the indicator light alarm and sound alarm, and the LCD display results at the same time, which is intuitive and easy to distinguish.

Storage function: store no less than 100,000 tests, and can export the data through the standard USB interface, read and analyze through the PC upper software.

3. Performance parameters

Using technology Ultra-wideband pulsed microwave reflection method and thermal conductivity method

Inspectable container material, capable of detecting different materials such as iron, aluminum, plastic, glass and ceramic

Types of liquid that can be inspected Flammable, explosive, corrosive and dangerous liquid

Inspectable container specifications 1. Plastic/glass/ceramic:

Volume: not less than 100ml, height not less than 3cm

Diameter: greater than 30mm and less than 200mm

Maximum height: unlimited

Wall thickness: not more than 8mm

2. Metal container:

Volume: not less than 100ml, height not less than 3cm

Diameter: greater than 30mm and less than 150mm

Maximum height: unlimited

Wall thickness: not more than 0.5mm

Detectable liquid: The instrument can alarm flammable or dangerous liquids in the following sealed containers: 93# gasoline, kerosene, diesel, ether, isopropyl ether, petroleum ether, acetaldehyde, ethylene glycol, nitrobenzene, propylene oxide , N-heptane, rosin, acetone, benzene, toluene, xylene, dichloroethane, ethanol, isopropanol, 70% ethanol, carbon disulfide, methanol, nitromethane, 70% isopropyl alcohol, paint thinner (nitrate Base solvent), trichloromethane, tetrahydrofuran, paint, n-hexane, hydrochloric acid, sulfuric acid, nitric acid, etc.

Liquid detection volume: not less than 100ml, height is not less than 3cm.

Boot time: 2.3s, no warm-up

Analysis time: Insulated container (plastic, glass, ceramic container): less than 1 second

Conductive container (aluminum can, iron can): less than 4 seconds

Alarm mode: sound, light, LCD display

Four, system function

Database storage: store no less than 100,000 tests and export data through standard USB interface

Read and analyze by PC upper software

Language: switch between Chinese system and English system

Adjustable brightness: Adjustable display brightness

Parameter setting: It is convenient for after-sales engineers to set the working parameters of the liquid detector according to the specific environment

Accuracy adjustment: adjust the recognition accuracy of the software by setting values

Self-checking function: The instrument has the device self-checking function, which can prevent a large number of random reports and false positives, and improve the inspection accuracy of the machine

V. Basic parameters

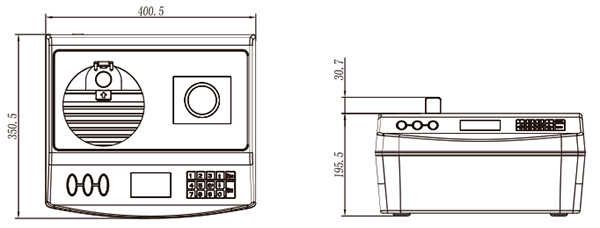

Size 350.5mm(W)*400.5mm(L)*195.5mm(H)

Weight ≤9Kg

Maximum power <20W

Leakage current The leakage current when the equipment is working meets the safety requirements of electronic equipment, less than 5mA

6. Use environment

Working temperature/humidity -10℃~55℃; 0%~90%

Working voltage AC 180V-240V (50/60Hz)

Atmospheric pressure 86kPa~106kPa

Follow us

Follow us